【Origin Pic】 |

|

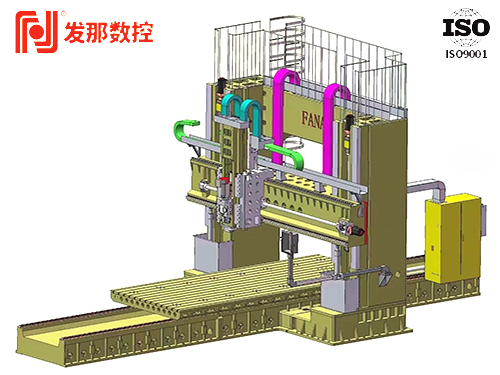

Product

CategoriesMachine features

Fixed beam gantry machining center machine tool is a beam fixed, workbench moving, gantry frame type machining center, on the basis of inherits the traditional gantry rigidity, good stability and other characteristics, the introduction of digestion and absorption of advanced design concepts, the use of finite element method for mechanical analysis, reasonable reinforcement, reasonable distribution of mass, so that the overall rigidity of the machine tool is strong, Static accuracy and dynamic performance are stable and reliable, and it is an advanced equipment with high efficiency, high precision and high reliability.

The machine tool can efficiently and accurately complete the milling, drilling, boring, reaming, tapping and other complex surface multi-process processing of parts. The right Angle milling head and universal milling head can be selected to achieve a clamping of parts and complete the processing of the top, front, back, left and right side of the parts. It is especially suitable for mechanical manufacturing, mold and complex surface processing. Widely used in general machinery, aviation, aerospace, automotive, nuclear industry, energy, mold, locomotive, heavy machinery, construction machinery, ships, machine tools, electronics, printing, textile and other manufacturing industries.

Technical parameter

item |

unit |

FA5227HE |

|||

ability |

Table size |

mm |

5000*2100 |

||

T Slot size |

mm |

28 |

|||

Table bearing |

kg |

15000 |

|||

Pass width of gantry |

mm |

2700 |

|||

Distance from spindle end face to table surface |

mm |

300-1200 |

|||

X-axis travel |

mm |

5000 |

|||

Y1-axis travel |

mm |

2500 |

|||

Y2-axis travel |

mm |

2500 |

|||

Z-axis travel |

mm |

900 |

|||

Principal axis |

Taper hole |

|

BT50 |

||

Spindle sleeve diameter |

mm |

φ190 |

|||

Maximum speed |

r/min |

4000 |

|||

Motor power |

KW |

22/26×2 |

|||

feed |

Rapid migration |

X |

m/min |

10 |

|

Y1/Y2 |

m/min |

10 |

|||

Z |

m/min |

10 |

|||

Cutting in |

X |

m/min |

6 |

||

Y1/Y2 |

m/min |

6 |

|||

Z |

m/min |

6 |

|||

Feed power |

X |

NM |

30 |

||

Y1/Y2 |

NM |

30 |

|||

Z |

NM |

30 |

|||

rail |

X |

|

2 ball guide rails |

||

Y |

|

2 roller guides |

|||

Z |

|

2 roller guides |

|||

precision |

Three-axis positioning accuracy |

|

MM |

±0.018 |

|

Repeated positioning accuracy |

triaxial |

mm |

0.02 |

||

Machine weight (±5%) |

Kg |

52000 |

|||

Numerical control |

Standard configuration |

|

FANUC-0iMF PLUS |

||