【Origin Pic】 |

|

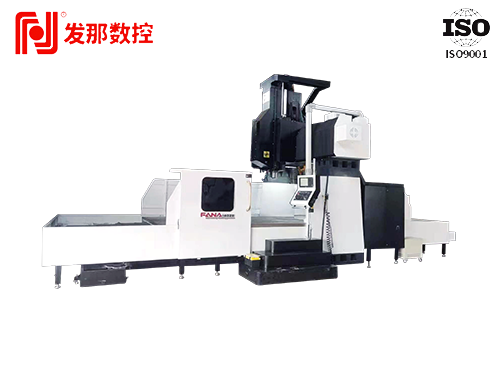

Product

Categories| Model | Unit | FA3028HE | FA4028HE | FA6028HE | |

| Workbench | Bench size | mm | 3000×2200 | 4000×2200 | 6000×2200 |

| T-slot | mm | 22 | 22 | 22 | |

| Maximum load bearing | Kg | 10000 | 12000 | 12000 | |

| Travel | X-axis travel | mm | 3000 | 4000 | 4000 |

| Y-axis travel | mm | 2800 | 2800 | 2800 | |

| Z-axis travel | mm | 1000 | 1000 | 1000 | |

| Distance from spindle end face to table | mm | 90-1090 | 90-1090 | 200-1200 | |

| Distance between columns | mm | 2800 | 2800 | 2800 | |

| Spindle | Spindle nose taper | BT50∮190 | BT50∮190 | BT50∮190 | |

| Spindle speed | r/min | 6000 | 6000 | 6000 | |

| Spindle motor | βiP30 | a22 | a22 | ||

| Three axes | Three-axis motor | NM | β40/β40/β40 | a40/a30/a30 | a40/a30/a30 |

| X-axis connection | Reducer 1:4 | Reducer 1:4 | Reducer 1:6 | ||

| Y Z-axis connection | Direct connection | Direct connection | Direct connection | ||

| Feed | Fast moving speed | m/min | 10/10/8 | 10/10/8 | 10/10/8 |

| Cutting feed rate | m/min | 6 | 6 | 6 | |

| Rail | X-axis guide configuration | mm | 55 rollers 2 /12 sliders | 55 rollers 2 /12 sliders | 55 rollers 2 /14 sliders |

| Y-axis guide configuration | mm | 55 rollers 2 /4 sliders | 55 rollers 2 /4 sliders | 55 rollers 2 /4 sliders | |

| Z-axis guide configuration | mm | Hard track | Hard track | Hard track | |

| Lead screw | X-axis screw configuration | mm | 80-20 | 80-20 | 80-20 |

| Y-axis screw configuration | mm | 63-16 | 63-16 | 63-16 | |

| Z-axis screw configuration | mm | 50-10 | 50-10 | 50-10 | |

| Precision | Positioning accuracy | mm | ±0.01/300 | ±0.01/300 | ±0.01/300 |

| Repeated positioning accuracy | mm | ±0.008/300 | ±0.008/300 | ±0.008/300 | |

| Optical machine ±5% | Kg | 28800 | 32800 | 45800 | |

| Standard configuration | ✤ Fanuc/Siemens/Mitsubishi Systems ✤. Belt spindle ✤, closed electric box ✤, air conditioner of electric cabinet ✤, electronic handwheel ✤. Spindle Hydraulic System | ✤. Spindle oil cooling system ✤, automatic tool change system ✤, automatic cooling system ✤, double helix chip extractor ✤. Chain chip extractor ✤. Vertical arm operating box ✤. Pedal spindle tool release device | ✤. Main shaft processing blowing device ✤, double cylinder counterweight balancing device ✤, semi-closed machine tool guard ✤. Working light and warning light ✤.USB interface and RS232 transmission interface | ||

| Optional configuration | ✤.Z axis rail ✤.Y, Z axis reducer ✤. Gear box ✤. Disc cutter library BT50-24T ✤. Right Angle milling head | ✤. Workpiece measurement ✤. Rotary table ✤. Grating ruler ✤. Ethernet transmission | |||