|

|

Product

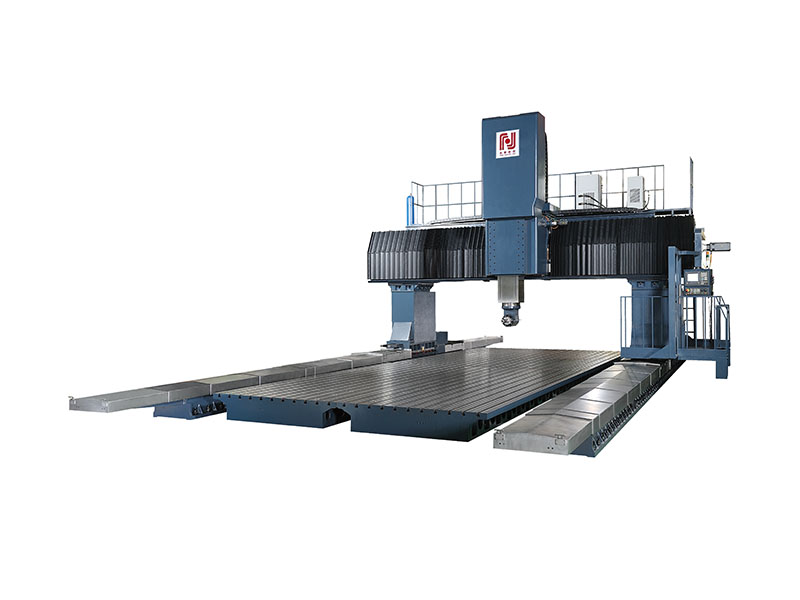

CategoriesThe X-axis adopts an integral gantry frame for movement,and the driving torque is not affected by the load.The machine tool has sensitive response and good dynamic characteristics.

Compared with the mobile layout products of the workbench,this series of products has strong load-bearing capacity and significantly reduces the footprint.

Two AC servo motors are used on both sides of the X-axis,combined with a gear reduction mechanism and bed rack,to achieve double servo mechanical and electrical clearance of the gantry shaft ,with higher accuracy.

X.The Y-axis guide rail adopts imported heavy-duty roller linear guide rails,which are sensitive to movement,have no crawling at low speeds,and have high positioning accuracy.

Full closed-loop control ensures the positioning accuracy and stability of the machine tool.

Multipe automatic or manual accessory milling heads can be selected,and the parts can be automatically processed on five sides through one clamping.A vertical and horizontal composite tool library can be selected at the same to automatically replace the cutting tools for the automatic right and automatic extension head,achieving automati processing and greatly improving work efficiency.

| Machine model | Unit | FA10045HMD | FA12045HMD | FA14055HMD |

|---|---|---|---|---|

| Worktable | ||||

| Workable size | mm | 1000*3000 | 12000*3000 | 14000*4000 |

| T-slot | mm | 28 | 28 | 36 |

| Travel | ||||

| X axis travel | mm | 10500 | 12500 | 14500 |

| Y axis travel | mm | 5000 | 5000 | 6000 |

| Z axis travel | mm | 1250 | 1250 | 1500 |

| Spindle nose to worktble | mm | 550-1800 | 550-1800 | 700-2200 |

| Distance between two columns | mm | 4500 | 4500 | 5500 |

| Spindle | ||||

| Spindle taper/diam | BT50ϕ190 | BT50ϕ190 | BT50ϕ190 | |

| Spindle speed | rpm/min | 6000 | 6000 | 6000 |

| Spindle motor | kw | 30 | 30 | 30 |

| Feed | ||||

| XYZ motors | kw | 6/8/8 | 6/8/8 | 6/6/6 |

| Cutting feed | m/min | 4 | 4 | 4 |

| 其它 Others | ||||

| Controllter | Standard:Siemenscontrol,option:Mitsubishi or Fanuc control | |||

| The three-axis travel and the load-bearing capacity of the worktable can be customized according to customer requirements | ||||

| Machine model | Unit | FA16055HMD | FA18065HMD | FA20065HMD |

|---|---|---|---|---|

| Worktable | ||||

| Workable size | mm | 16000*4000 | 18000*5000 | 20000*5000 |

| T-slot | mm | 36 | 36 | 36 |

| Travel | ||||

| X axis travel | mm | 16500 | 18500 | 20500 |

| Y axis travel | mm | 6000 | 7000 | 7000 |

| Z axis travel | mm | 1500 | 1500 | 1500 |

| Spindle nose to worktble | mm | 700-2200 | 1000-2500 | 1000-2500 |

| Distance between two columns | mm | 5500 | 6500 | 6500 |

| Spindle | ||||

| Spindle taper/diam | BT50ϕ190 | BT50ϕ190 | BT50ϕ190 | |

| Spindle speed | rpm/min | 6000 | 6000 | 6000 |

| Spindle motor | kw | 30 | 30 | 30 |

| Feed | ||||

| XYZ motors | kw | 6/6/6 | 6/6/6 | 6/6/6 |

| Cutting feed | m/min | 4 | 4 | 4 |

| Others | ||||

| Controllter | Standard:Siemenscontrol,option:Mitsubishi or Fanuc control | |||

| The three-axis travel and the load-bearing capacity of the worktable can be customized according to customer requirements | ||||